It’s black. It’s a bit bigger than a breadbox. It has four knobby wheels, a water nozzle sticking out the back and it can really scoot.

It’s the one-fifth-scale model amphibious vehicle that a team of Vanderbilt engineering students designed and built for a national competition, called the Model-Based Amphibious Racing Competition (MBARC), which took place in mid-January at the Camp Pendleton Marine Corps Base in southern California.

The Vanderbilt model amphibious vehicle posed in front of an actual amphibious infantry fighting vehicle. (Courtesy of Tom Withrow / Vanderbilt University)

The contest kicked off the new annual competition sponsored by the Defense Advanced Research Project Agency. It is part of the agency’s effort to revolutionize the way in which military vehicles are designed and manufactured, called the Adaptive Vehicle Make program. Vanderbilt’s Institute for Software Integrated Systems is playing a key role in developing software for the program.

In the first competition, Vanderbilt undergraduates went up against a similar team from UC Berkeley and a team of graduate students from MIT.

The contest consisted of four “missions” over a course that was laid out on a beach with both land and water legs. The vehicles weren’t judged on their times alone, but also on how close their performance compared to the predictions made by the computer modeling software that the students used to design them.

Vanderbilt students working on their model in between trials. (Courtesy of Tom Withrow / Vanderbilt University)

The Vanderbilt vehicle took first place in the first three missions. The final mission involved carrying a heavy payload around the course. The Vanderbilt students elected to carry a relatively light weight and went first, which allowed the MIT team to select a payload that was just heavy enough to edge out the Vanderbilt team in the final score. The Berkeley team came in a distant third.

“We didn’t win the overall race,” said Assistant Professor of the Practice in Mechanical Engineering Tom Withrow. “But we had awesome speed and flawless performance.” He taught the fall semester course specifically devoted to designing and building the radio-controlled amphibious model.

“Our vehicle, with its Kevlar body, suspension system and water jet propulsion really intimidated the other teams and its speed surprised and impressed the Marine Corps observers,” Withrow said.

According to a blog entry by one of the MIT team members, “Vanderbilt University showed up with a much more fearsome and customized R/C truck mod which had a fabricated frame and hull, but stock R/C truck driveline and suspension components…. This thing was a rocket on land and also quick in the water because of its thrust-vectoring jet pump.”

“When we were planning this competition we never dreamed you guys would get so far and do so well,” said Janos Sztipanovits, the director of ISIS. “You stood up against the best engineering students in the country.”

Sztipanovits added that DARPA officials are extremely happy with the outcome. The AVM program is the agency’s biggest program and the competition was the first test of the software tools that they are developing which they hope can dramatically reduce the time and cost of developing new military systems. So they were relieved that the students were able to use these tools to produce vehicles that worked so well.

The student team consisted of Grant Brennecke, senior, mechanical engineering; Kevin Bush, junior, mechanical engineering; Brandon Dimmig, junior, mechanical engineering; Ryan Hess, junior, mechanical engineering; Nathan Hollis, senior, mechanical engineering and mathematics; Peter Holly, senior, computer science; Alok Hota, junior, computer engineering; Andrew Leopold, senior, mechanical engineering; Christopher Twedell, junior, mechanical engineering and physics; and Dexter Watkins, senior, mechanical engineering.

“None of us expected that we would put in as much time as we did, but none of us regret it,” said Hollis. “It was the highlight of my engineering career so far.”

The class was valuable training in real-world engineering with hard and fast deadlines and limited resources. “I wanted the course to be the biggest challenge the students ever had,” said Withrow. “The students made all the decisions so they could learn what it’s like to be a practicing engineer.”

“At the beginning we had a number of fantastic ideas, like a retractable suspension, but we quickly realized that they just weren’t practical,” Hota commented.

In just three months, the team produced a number of different prototypes. Initially, they had two different versions, one for land and the other for the water. Their first land prototype ran 30 seconds before it failed. They installed their first water jet drive system in a plastic Rubbermaid™

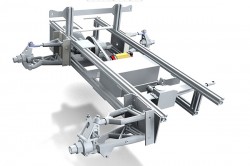

Computer aided design model of the vehicle’s chassis that the students produced using the software tools developed for AVM. (Courtesy of Tom Withrow / Vanderbilt University)

tub and tested it in the pool outside Olin Hall. They tested the water-going capabilities of their final prototype in the pond in Centennial Park.

The student engineers had major problems with overheating, which they solved by designing and installing two water-cooling systems with a radiator. They also had difficulty sealing the lid to keep water from shorting out the electronics, which they mitigated by adding a sump and a miniature bilge pump.

The students made a list of the major lessons they learned. The first is to start early on everything because tasks always take much longer than you expect. Second is to keep your ideas realistic. Third is to document everything you do, otherwise you won’t remember the results of what you’ve done when you really need them in the future. Finally, constant communication is essential in team effort of this sort.

“The job you did makes AVM look good…and it makes Vanderbilt look really good,” Ted Bapty, the ISIS senior research scientist who directs one of the key AVM projects, told the students at a reception held in their honor.

(Courtesy of Tom Withrow / Vanderbilt University)